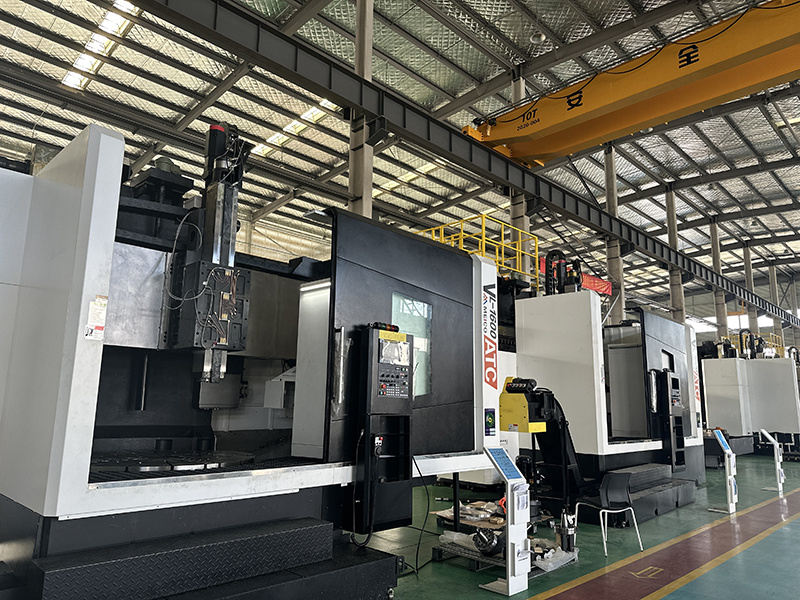

Large Heavy-Duty CNC Vertical Lathe

Release time:

2025-01-09

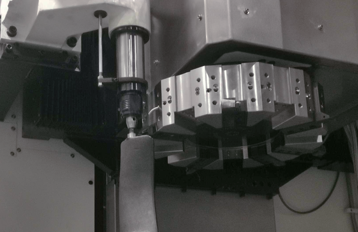

The Meishen Meike VL1000-VL1600 series models are equipped with roller linear guides on the X-axis as standard. The roller linear guides feature high precision, high rigidity, and low friction, ensuring the stability and accuracy of the machine tool during high-speed and high-precision machining processes. In addition, the roller linear guides also reduce wear and heat generation, thereby extending the service life of the machine tool.

Large heavy-duty CNC vertical latheThe design is crucial for ensuring its high precision, high rigidity, and long-term stability. Meishen Meike CNC vertical machine toolsThe X-axis main sliding table adopts a front and rear rail design, which has a direct impact on the machine's central stability.

The front and rear rail design usually means that the sliding table moves in the X-axis direction through two sets of guide rails. This design helps to distribute the load, improve the machine's load capacity, and also helps to maintain the machine's stability during the processing. Especially during large heavy cutting, the machine needs to withstand huge cutting forces and vibrations, making this design particularly important.

The Meishen Meike VL1000-VL1600 series models are standard equipped with roller linear guides on the X-axis, and roller linear guides havehigh precision, high rigidity, and low frictioncharacteristics, ensuring the stability and accuracy of the machine during high-speed, high-precision processing. In addition, roller linear guides can also reduce wear and heat generation, thereby extending the machine's service life.

At the same time,this series also offers hard rails as an optional choice. Hard rails usually have higher rigidity and load capacity, suitable for processing scenarios that require withstanding extremely high cutting forces. However, the friction coefficient of hard rails is relatively high, which may have some impact on the machine's precision and speed. Therefore, when deciding whether to use hard rails, it is necessary to weigh based on specific processing needs and conditions.

The design of the X-axis main sliding table of the Meishen Meike VL1000-VL1600 series fully considers the machine's stability, precision, and load capacity. By adopting a front and rear rail design and roller linear guides (or optional hard rails), this series can meet the needs of various large heavy cutting processes and ensure processing quality and efficiency.

Large heavy-duty CNC vertical lathes have a wide range of applications in modern manufacturing, mainly including but not limited to the following aspects:

Processing large and heavy workpieces:

These lathes are particularly suitable for processing large diameter and relatively short length large and heavy workpieces, such aslarge shaft parts, gears, hubsand so on.

Their bed length and rigidity design can withstand huge cutting forces and vibrations, ensuring the stability and accuracy of the processing.

High precision processing:

CNC vertical lathes usually use a CNC system with X-axis feed, combined withprecise mechanical structure designto achievehigh precisionprocessing.

Equipped with various precision measurement and detection devices further ensures the stability and reliability of the processed workpiece quality, suitable for workpieces with high processing precision requirements, such asprecision mechanical parts, aerospace partsand so on.

Multiple processing methods:

In addition to conventionalcuttingprocessing, CNC vertical lathes can also completethread turning, spherical turning, profiling, milling, and grinding, etc.various workpiece processing methods.

This versatility makes CNC vertical lathes have a wider range of applications in the machining field.

Widely used in multiple fields:

CNC vertical lathes are used in the automotive industry to produce engine components, such as high-precision turned parts of key areas like crankshafts.

In the aerospace field, due to the need for extremely high precision and surface quality, CNC vertical lathes are widely used to manufacture turbine blades and other important structural components of aircraft engines.

In addition,in shipbuilding, oil exploration equipment, semiconductors, wind power equipment manufacturing, and other fields, CNC vertical lathes also play an important role.

Large heavy-duty CNC vertical lathes, with theirhigh precision, high rigidity, high stability, multifunctionality, and wide application range, play an irreplaceable role in modern manufacturing. They can meet variouscomplex parts processing needs, providing professional solutions for your enterprise production! You have parts, I have solutions, assisting efficient production!

E-mail:meishenmeike@163.com

Zip Code: 215300

Add: No.18,Huangziliang Rd,Qutang Town, Hai'an City,Jiangsu

MEICO

Follow us