Heavy cutting turret crane: How to ensure precise and stable feed?

Release time:

2025-03-12

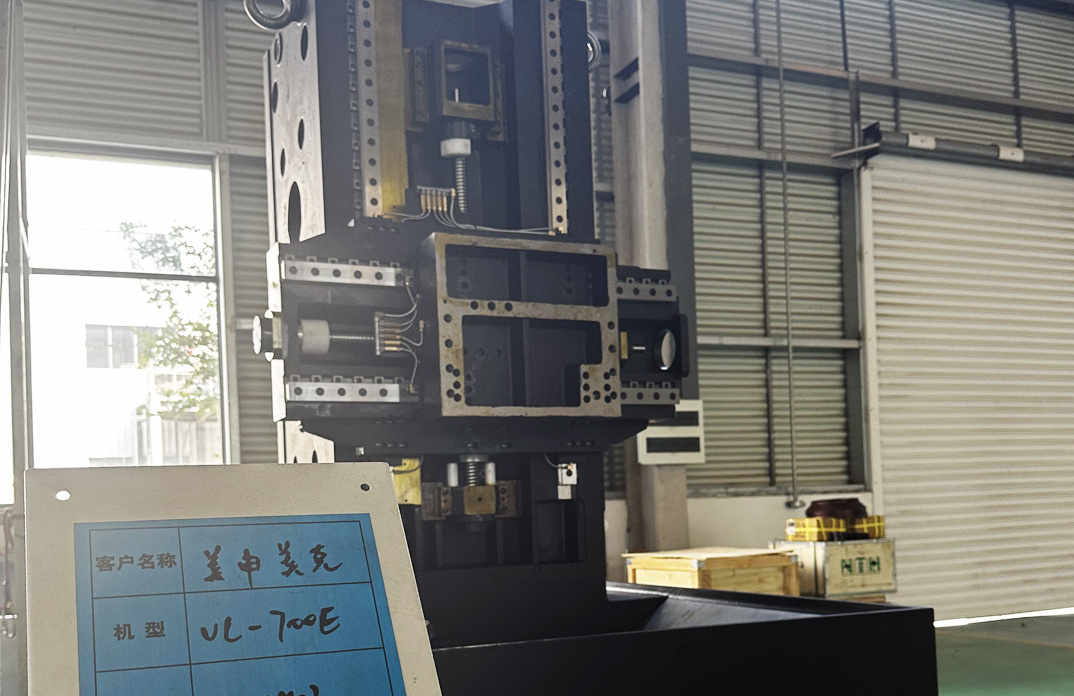

Jiangsu Meishen Meike 400-1000 turret crane is equipped with a 250 strong turret, which not only has higher rigidity and cutting force, but also enables faster tool changing operations, further improving machining efficiency. At the same time, the enlarged inclined body design makes chip removal smoother, avoiding the decrease in machining quality and machine damage caused by chip accumulation.

The heavy cutting turret crane has become a processing equipment in many industrial fields due to its processing capability and high production efficiency. In order to ensure precise and stable feed during the machining process of heavy cutting turret machines, manufacturers continuously adopt X-feed technology and materials to improve the overall performance of the machine tool.

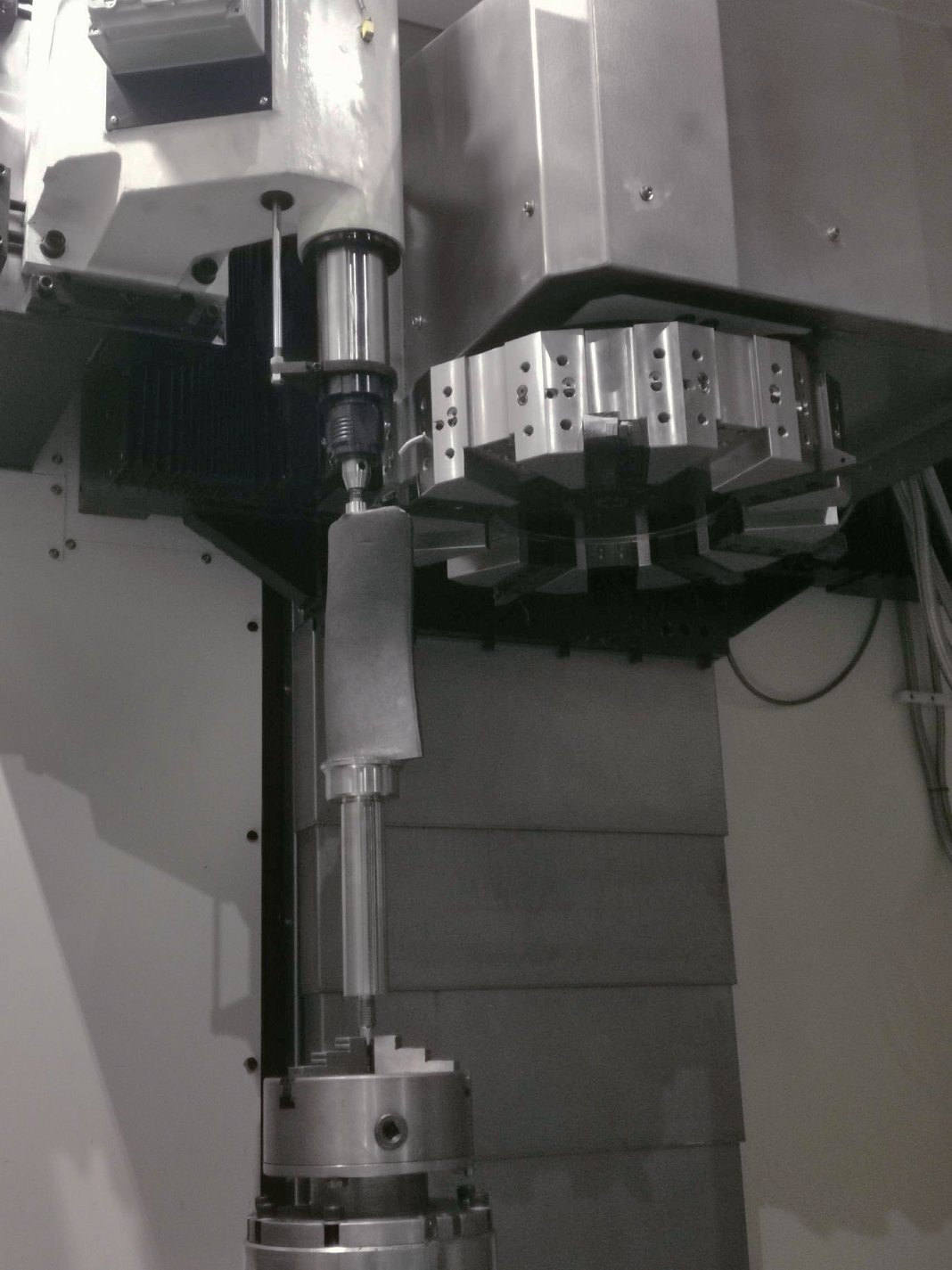

The spindle head of Jiangsu Meishen Meike MECIO heavy cutting turret crane adopts NN series bearings, which are uniquely designed to withstand both axial and radial loads, and can maintain excellent stability even during long-term cutting processes. The increase in spindle specifications not only enhances cutting force, but also enables the machine tool to maintain high precision under heavy cutting conditions. The original imported bearings ensure the high quality and long service life of the spindle head.

The sheet metal design of the turret crane fully considers the principles of human mechanics, making the operation more convenient and comfortable. At the same time, the unified design of inspection makes the daily maintenance and inspection of machine tools simpler and more efficient, greatly reducing downtime and maintenance costs.

In order to meet different processing needs, the heavy cutting turret crane also offers multiple optional configurations. For example, the addition of grating rulers enables machine tools to achieve higher positioning accuracy and repeatability during the machining process. The introduction of specialized fixtures and automatic measurement systems for workpieces has further improved processing efficiency and quality.

In terms of feed system, the heavy cutting turret crane adopts roller tracks with overload, which not only improves the load-bearing capacity and stability of the machine tool, but also makes the feed motion smoother and more accurate. The box shaped structure at the bottom of the equipment further enhances the overall rigidity of the machine tool, and can maintain excellent machining accuracy even under heavy cutting conditions.

In addition, the Jiangsu Meishen Meike 400-1000 turret crane is equipped with a 250 strong turret, which not only has higher rigidity and cutting force, but also enables faster tool changing operations, further improving machining efficiency. At the same time, the enlarged inclined body design makes chip removal smoother, avoiding the decrease in machining quality and machine damage caused by chip accumulation.

The Meishen Meike heavy cutting turret crane adopts multiple X-feed technologies and design features to ensure precise and stable feed. From spindle head to sheet metal design, from optional configurations to feed systems, every detail fully reflects the manufacturer's ultimate pursuit of quality and performance. These innovative designs and technological features not only enhance the machining capacity and production efficiency of machine tools, but also inject new impetus into the development of the manufacturing industry.

More information

E-mail:meishenmeike@163.com

Zip Code: 215300

Add: No.18,Huangziliang Rd,Qutang Town, Hai'an City,Jiangsu

MEICO

Follow us