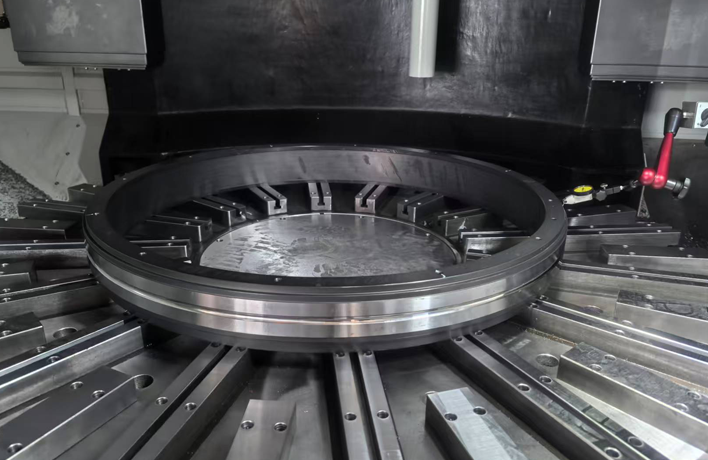

CNC vertical lathe with a turning diameter of 3 meters

Release time:

2025-03-27

The CNC vertical lathe has the characteristics of compact structure and good working stability, which can maintain the working accuracy of the lathe for a long time. Suitable for workpieces that require high machining accuracy, such as precision mechanical parts, aerospace parts, etc.

The CNC vertical lathe with a rotating diameter of 3 meters is an important member of large metal heavy cutting machine tools.

1、 Basic characteristics

Large scale processing capability:

A turning diameter of 3 meters means that this type of lathe can process large and heavy workpieces with larger diameters and relatively shorter lengths.

Suitable for workpieces of various shapes such as cylinders, cones, spheres, etc., such as large shaft parts, gears, hubs, etc.

High precision machining:

The CNC vertical lathe has the characteristics of compact structure and good working stability, which can maintain the working accuracy of the lathe for a long time.

Suitable for workpieces that require high machining accuracy, such as precision mechanical parts, aerospace parts, etc.

Multiple processing methods:

In addition to conventional cutting machining, various machining methods such as threading, ball turning, profiling, milling, and grinding can also be completed with the help of auxiliary devices.

This makes CNC vertical lathes have a wider range of applications in the field of mechanical processing.

2、 Working principle

Workpiece clamping and rotation:

The workpiece is clamped on the spindle of the vertical lathe, which is driven to rotate by a motor.

The upright design of the spindle makes it convenient to clamp the workpiece on a horizontal worktable, and the mass and cutting force of the workpiece are borne by the rotating guide rail between the worktable and the base, reducing the load on the spindle and its bearings.

Cutting tool movement:

The cutting tool is installed on the tool holder and moves in a straight or curved line through a feed mechanism.

The feed mechanism usually consists of a feed slide, a feed screw, and a feed motor, which are used to control the position and movement speed of the cutting tool on the workpiece.

Cutting process:

When the spindle rotates and drives the workpiece to rotate, the cutting tool comes into contact with the workpiece and performs cutting under the drive of the feed mechanism.

During the cutting process, the feed rate and cutting depth of the cutting tool can be adjusted according to the machining requirements to achieve precise machining results.

At the same time, lubricating coolant is injected into the cutting area to provide cooling and lubrication, reducing heat and friction between the workpiece and the tool, thereby improving machining quality and tool life.

3、 Purchase suggestions

Clear requirements:

Before purchasing, it is necessary to clarify the requirements for the size, shape, material, and machining accuracy of the processed workpiece.

Choose the appropriate lathe model and configuration according to the requirements.

On site testing:

Before purchasing, you can come to Meishen Meike for on-site testing to check the performance and stability of the equipment. (Customer Training)

By testing the machine, one can intuitively understand the processing capability and precision level of the equipment.

after-sale service:

Meishen Meike provides comprehensive and timely after-sales service to ensure that the equipment receives timely and effective maintenance and support during use.

The CNC vertical lathe (with a turning diameter of 3 meters) has the characteristics of large machining capacity, high-precision machining, and multiple machining methods, and has a wide range of application prospects in the field of mechanical machining.

More information

E-mail:meishenmeike@163.com

Zip Code: 215300

Add: No.68,Huangziliang Rd,Qutang Town, Hai'an City,Jiangsu

MEICO

Follow us