Application of CNC vertical lathe in precision machining of wind turbine bearings

Release time:

2025-02-08

Meishen Meike CNC vertical lathe, with its high precision and stability, can complete all machining processes of the workpiece after one clamping, easily cope with these challenges, and ensure that the bearings after heat treatment can still maintain high precision and quality.

With the continuous growth of global demand for renewable energy, the wind power industry has ushered in unprecedented development opportunities. As a key component in wind power equipment, the quality and performance of wind turbine bearings directly affect the operational efficiency and safety of the entire wind turbine unit. In order to meet the requirements of high precision, high strength, and high wear resistance of wind turbine bearings, CNC vertical lathes play an important role in the precision machining of wind turbine bearings.

Wind turbine bearings usually use high-quality alloy steel or stainless steel as raw materials, which have become the choice in wind power equipment due to their high strength, high hardness, and good wear resistance. However, these high-performance materials also place higher demands on processing equipment. As a high-precision and high-efficiency machining equipment, CNC vertical lathes have been widely used in the field of wind turbine bearing machining due to their performance and stability.

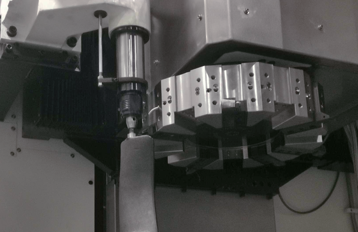

The CNC vertical lathe can achieve precise execution of various machining methods, such as turning and milling, through the control of the CNC system. These processing methods can accurately remove materials and form complex shapes and precise dimensions required for wind turbine bearings. During the machining process, the high-precision spindle and feed system of the CNC vertical lathe ensure the stability and consistency of machining accuracy, thereby meeting the high-precision machining requirements of wind turbine bearings.

Especially in the precision machining stage, the role of CNC vertical lathes is even better. By adopting advanced measurement techniques and detection methods such as laser rangefinders and coordinate measuring machines, CNC vertical lathes can monitor and adjust errors in the machining process in real time. These high-precision measuring devices ensure that the machining accuracy of bearings meets design requirements and even exceeds the limits of traditional machining methods.

As a manufacturer of CNC vertical lathes, Jiangsu Meishen Meike's CNC vertical lathes have advantages in the field of wind turbine bearing processing. Meishen Meike machine tool equipment not only has high precision and stability, but also has strong processing capabilities and adaptability, which can meet the processing needs of various complex shapes and sizes of wind turbine bearings. At the same time, Meishen Meike's CNC vertical lathe is also equipped with XJ's CNC system and user interface, allowing operators to easily set and adjust machining parameters, further improving machining efficiency and product quality.

Heat treatment is an important step in the processing of wind turbine bearings. Heat treatment can improve the hardness and strength of bearings, while eliminating internal stress, enhancing the wear resistance and service life of bearings. However, bearings after heat treatment often suffer from deformation and dimensional changes, which pose higher challenges for subsequent precision machining. Meishen Meike CNC vertical lathe, with its high precision and stability, can complete all machining processes of the workpiece after one clamping, easily cope with these challenges, and ensure that the bearings after heat treatment can still maintain high precision and quality.

E-mail:meishenmeike@163.com

Zip Code: 215300

Add: No.18,Huangziliang Rd,Qutang Town, Hai'an City,Jiangsu

MEICO

Follow us