Meishen Meike CNC Vertical Lathe

Release time:

2025-01-15

Meishen Meike CNC vertical lathes are also widely used in various fields such as mold processing, valve manufacturing, wind power equipment manufacturing, engineering machinery manufacturing, automotive manufacturing, and complex workpieces. The workpieces in these fields typically have characteristics such as complex shapes, high precision, and high processing difficulty. Meishen Meike equipment, with its ZY performance and stable quality, can meet the processing needs of these fields.

Meishen Meike equipment provides productivity support for the machining field with its ZY design and exquisite craftsmanship. The equipment adopts a series of advanced technologies and materials, ensuring its superior performance in processing accuracy, rigidity, and stability.

The base adopts a sturdy box-type structure design, which not only enhances the overall rigidity of the equipment but also effectively reduces vibration and deformation, thereby ensuring the stability of processing accuracy.

The base material is made of high-quality Meehanite cast iron, which has excellent mechanical properties and thermal stability, capable of withstanding high-intensity machining and long-term use, further enhancing the durability and stability of the equipment.

The one-piece base design reduces assembly errors and improves the overall precision and rigidity of the equipment. This design makes the base more stable when bearing processing loads, ensuring the consistency of processing quality.

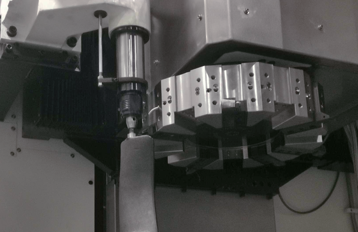

The gearbox and spindle adopt a high-rigidity combined design, ensuring the efficiency and stability of power transmission.

The spindle uses a BT50+ full tooth connection method, which increases the contact area of the connection, enhances the cutting force, making the tool more stable during the machining process.

The spindle has high torque characteristics, combined with the full tooth connection method, can easily handle various complex cutting tasks, improving processing efficiency and quality.

The spindle motor adopts a direct gear transmission method, which can increase torque output by 20% compared to traditional belt transmission. This not only enhances the cutting capability of the equipment but also makes power transmission more direct and efficient, reducing energy loss and vibration.

The Z-axis slide uses German NF1 special steel, which is precisely processed in Taiwan. This steel has excellent wear resistance and fatigue resistance, ensuring that the slide maintains good precision and stability under long-term, high-intensity use. Meanwhile, Taiwan's precision processing technology further enhances the manufacturing precision and surface quality of the slide.

Meishen Meike equipment provides high-performance and high-precision machining solutions for the machining field with its ZY design, exquisite craftsmanship, and advanced materials. The equipment not only features a high-rigidity and high-stability base design but also adopts advanced gearbox and spindle combination methods as well as direct gear transmission technology for the spindle motor, resulting in outstanding performance in cutting capability, processing efficiency, and processing quality. Additionally, the high-quality materials and precision processing technology used in the Z-axis slide further enhance the overall performance and durability of the equipment.

Meishen Meike CNC machine tools are widely used in various machining fields due to their high precision, high rigidity, and high stability. The following is a specific analysis of the types of workpieces suitable for Meishen Meike equipment.

1. Large and Heavy Workpieces

Meishen Meike equipment, especially its large CNC vertical lathes, such as the 3-meter CNC vertical lathe VL-3000ATC, is specifically designed for the machining of large and heavy workpieces. These machines have strong cutting capabilities and load-bearing performance, easily meeting the machining needs of various large workpieces. Whether it is complex components in the aerospace field or heavy equipment parts in the energy industry, Meishen Meike equipment can provide stable and reliable machining support.

2. Complex Shape Workpieces

The spindle system of Meishen Meike equipment has a strong structure and high rotational precision, ensuring stability and accuracy during the machining process. Therefore, these machines are suitable for machining various complex-shaped workpieces, including inner and outer cylindrical surfaces, inner and outer conical surfaces, end faces, grooves, arc surfaces, various curved surfaces, and threads. These machines can produce high-precision, high-quality workpieces, meeting the high precision requirements of machining.

3. Workpieces of Various Materials

Meishen Meike machine tools adopt advanced CNC systems and precise mechanical structures, enabling them to handle various difficult-to-machine materials and large cutting volumes. Whether it is hard alloys, stainless steel, titanium alloys, or other special materials, Meishen Meike equipment can provide stable machining performance and efficient cutting capabilities.

4. Automotive Industry Workpieces

Meishen Meike CNC vertical lathes are also widely used in the automotive manufacturing field. Their high precision and high efficiency machining capabilities can meet the automotive industry's high requirements for workpiece machining accuracy and efficiency. For example, the machining of key components such as engine blocks, cylinder heads, and crankshafts can be completed using Meishen Meike CNC vertical lathes.

5. Workpieces in Other Fields

In addition to the aforementioned fields, Meishen Meike CNC vertical lathes are also widely used in mold processing, valve manufacturing, wind power equipment manufacturing, engineering machinery manufacturing, and other fields. The workpieces in these fields typically have complex shapes, high precision, and high machining difficulty, and Meishen Meike equipment, with its ZY performance and stable quality, can meet the machining needs of these fields.

E-mail:meishenmeike@163.com

Zip Code: 215300

Add: No.18,Huangziliang Rd,Qutang Town, Hai'an City,Jiangsu

MEICO

Follow us