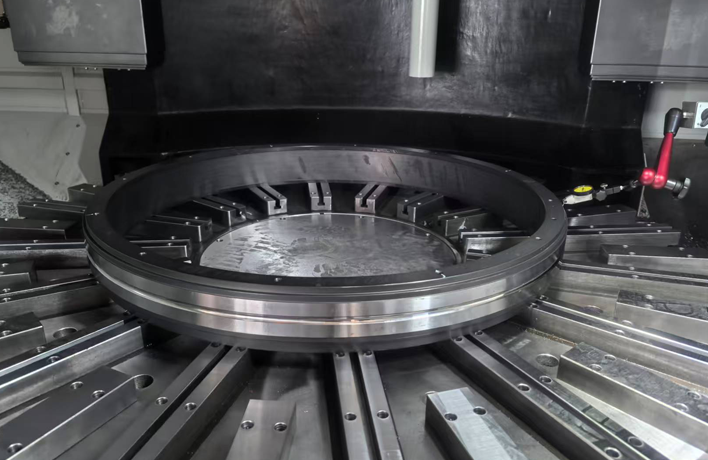

Meishen Meike CNC vertical lathe worktable base

Release time:

2025-07-08

In the field of high-end CNC Vertical Lathe machine tool equipment, the worktable base is the core component that carries machining loads and ensures equipment stability. Its design level directly determines the overall performance of the machine tool. The worktable base of Meishen Meike CNC vertical lathe adopts G-grade reinforced cast iron integrated molding technology, combined with symmetrical box structure and reinforced mesh rib plate design, to achieve the ability to withstand gravity compression and deformation resistance, providing solid guarantee for precision machining.

Material Innovation: Application of Advanced Reinforced Cast Iron

The Meishen Meike base is made of advanced cast iron material, which is endowed with high strength, high elastic modulus, and low internal stress characteristics through composition optimization and special melting processes. Compared to ordinary cast iron, its matrix strength is increased by more than 30%, and it can still maintain structural stability under heavy load conditions. This material characteristic reduces the deformation of the base to the micrometer level when subjected to cutting forces, workpiece weight, and dynamic loads, providing a basic guarantee for machine tool accuracy.

Structural Innovation: Mechanical Optimization of Symmetric Box Frame

The base adopts a fully enclosed symmetrical box structure, inspired by the arch mechanics principle in the field of architecture. Optimize the cross-sectional shape through finite element analysis to evenly distribute the load on the box wall panels and avoid stress concentration. Specific advantages include:

Thermal symmetry: The center of the column coincides with the base, forming a thermal symmetry layout, effectively reducing the impact of thermal deformation on machining accuracy;

Improvement in torsional stiffness: The inertia moment of the box shaped section is increased by 50% compared to traditional open structures, enhancing its torsional resistance;

Dynamic response optimization: Symmetrical design reduces vibration coupling effects, improving the dynamic stability of the machine tool by 40% during high-speed cutting.

Technological breakthrough: precision manufacturing of integrated molding technology

Different from traditional welding and assembly processes, Meishen Meike adopts precision mold integrated molding technology to achieve seamless manufacturing of the base. This process has three core advantages:

Structural integrity: eliminate the heat affected zone of welding, avoid the risk of fatigue cracking of welds, and extend the service life by more than twice;

Dimensional accuracy: Through one-time molding with molds, key dimensional tolerances are controlled to reduce subsequent processing volume;

Stress relief: Whole casting combined with vibration aging treatment ensures uniform distribution of internal stress in the material, and long-term deformation is less than 0.02mm/year.

Strengthening design: stiffness enhancement of mesh rib system

Inside the box structure, a mesh rib layout is adopted, and topology optimization design is used to achieve:

Load path optimization: The main rib plate is distributed along the stress streamline, and the secondary rib plate forms a honeycomb support, increasing local stiffness by 60%;

Balance between lightweight and rigidity: while ensuring rigidity, the rib thickness is optimized, resulting in a 15% reduction in weight compared to traditional designs;

Dynamic damping characteristics: The mesh structure forms a natural damper to suppress high-frequency vibrations.

Performance verification: Excellent performance under harsh working conditions

High rigidity design increases cutting parameters by 30% and shortens machining cycles by 20%;

The research and development of the worktable base for Meishen Meike CNC vertical lathe marks a breakthrough in the field of basic component design for high-end machine tools. Through the deep integration of materials science, structural mechanics, and advanced manufacturing processes, this base not only redefines the performance boundaries of machine tool bases, but also provides key machine tool equipment support for strategic industries such as aerospace and precision molds.

More information

E-mail:meishenmeike@163.com

Zip Code: 215300

Add: No.68,Huangziliang Rd,Qutang Town, Hai'an City,Jiangsu

MEICO

Follow us