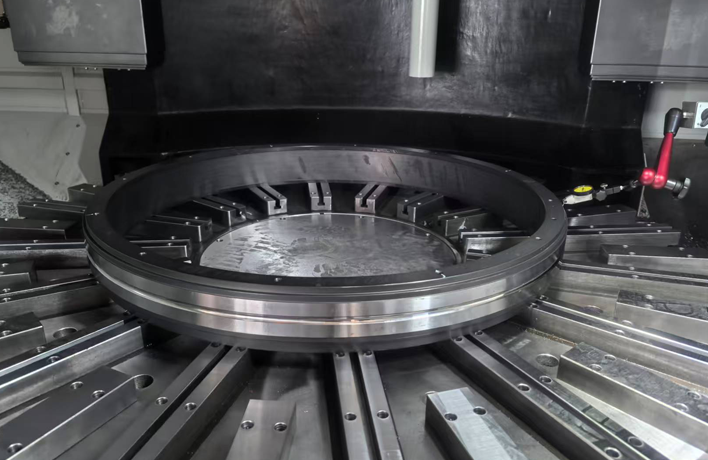

Numerical Control Vertical Lathe: Processing of Wind Power Equipment Accessories

Release time:

2025-07-08

Meishen Meike CNC vertical lathe, with its technological advantages, has demonstrated obvious competitiveness in the processing of core components such as bearing seats, locking discs, gearbox bodies, and wheel hubs, providing efficient and accurate solutions for wind power equipment manufacturers.

Against the backdrop of rapid development in the wind power industry, the machining accuracy, efficiency, and reliability of equipment components have become key factors determining the overall performance of wind turbines. Meishen Meike CNC vertical lathe, with its technological advantages, has demonstrated obvious competitiveness in the processing of core components such as bearing seats, locking discs, gearbox bodies, and wheel hubs, providing efficient and accurate solutions for wind power equipment manufacturers.

1、 High rigidity structure: suitable for processing large and heavy components

Wind power equipment accessories such as gearboxes, bases, and enclosures generally have the characteristics of large size, heavy weight, and complex structure. The Meishen Meike CNC vertical lathe adopts a high rigidity bed design, effectively suppressing vibration and deformation during the machining process, ensuring stable accuracy even under heavy load cutting. For example, when processing wheels with a diameter exceeding 2 meters, the equipment can withstand high torque cutting forces to ensure that the form and position tolerances (such as roundness and flatness) meet the requirements of μ m.

2、 Multi axis linkage and composite machining capability: meeting complex surface requirements

Wind power components such as planetary carriers, slewing bearings, torsion arms, etc. often involve asymmetric surface and porous machining. Meishen Meike equipment supports five axis linkage and milling combined processing, which can complete the processing of end faces, inner holes, threads, and complex surfaces in one go, reducing the number of clamping times and error accumulation. For example, when processing locking discs, the equipment uses dynamic interpolation technology to achieve synchronous processing of precision slots and threads, shortening the production cycle.

3、 Thermal stability control: ensuring high-precision machining

Wind power equipment requires high dimensional stability of accessories (such as controlling the clearance between bearing seats within 0.01mm). Meishen Meike CNC vertical lathe adopts a constant temperature cooling system and symmetrical layout design, effectively controlling the thermal deformation of key components such as spindle and guide rail. Combined with closed-loop temperature compensation technology, the equipment can maintain high repeatability positioning accuracy even during continuous operation, meeting the strict tolerance requirements of wind power components.

4、 Processing strategy: Improve production capacity and economy

In response to the demand for mass production in the wind power industry, Meishen Meike equipment achieves efficient cutting of hard alloy cutting tools through high-speed spindles and high-power servo drives. For example, when processing valve bodies, the equipment can simultaneously complete rough machining and semi precision machining. Combined with adaptive feed control technology, the material removal rate can be increased by more than 30%. In addition, the equipment supports an automatic tool change system (ATC), which reduces tool change time to 2 seconds and further shortens non processing time.

5、 Intelligent function: reduce the cost of manual intervention

The Meishen Meike CNC system integrates online detection and compensation functions, which can monitor the machining status in real time and automatically correct parameters. For example, when machining the spindle sleeve, the system adjusts the cutting amount through feedback data from a laser interferometer to ensure wall thickness uniformity. In addition, the equipment supports integration with MES systems to achieve production data traceability and process optimization, helping wind power enterprises build digital workshops.

6、 Industry customized design: tailored to meet the special needs of wind power

In response to the high anti-corrosion and high fatigue strength requirements of wind power accessories, Meishen Meike equipment provides special coated guide rails and enclosed protective structures to effectively resist the erosion of cutting fluids and metal debris. At the same time, the equipment can be equipped with a super large worktable (with a diameter of up to 5 meters) to meet the processing needs of giant parts such as wind turbine hubs, reducing the accuracy loss caused by segmented processing.

Meishen Meike CNC vertical lathe has the core advantages of high rigidity, multi axis linkage, thermal stability control, efficient processing, and intelligence, fully covering the processing pain points of wind power equipment accessories. From precise fitting of bearing seats to complex curved surfaces of wheel hubs, the equipment provides stable performance and efficient production capacity, helping the wind power industry achieve cost reduction, efficiency improvement, and reliability upgrades, becoming the preferred solution in the field of new energy equipment manufacturing.

More information

E-mail:meishenmeike@163.com

Zip Code: 215300

Add: No.68,Huangziliang Rd,Qutang Town, Hai'an City,Jiangsu

MEICO

Follow us