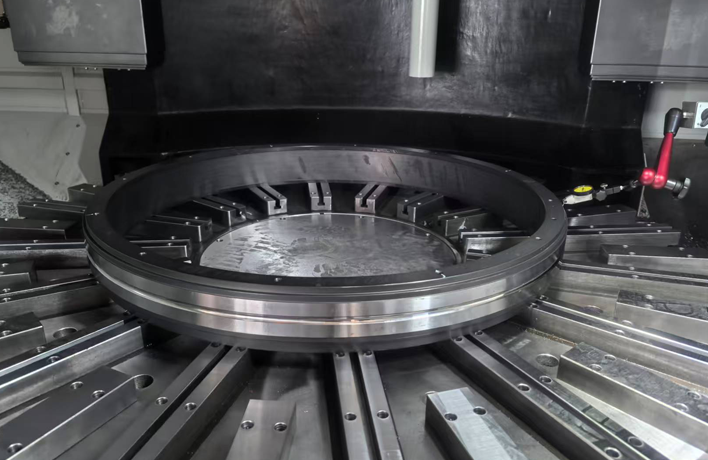

Journey of Processing Brake Discs and Industrial Machinery Components on CNC Vertical Lathes

Release time:

2025-05-28

CNC machining of brake discs can ensure the machining accuracy and quality of brake discs, and improve the reliability performance of automobiles.

CNC vertical lathe, also known as CNC vertical lathe, is a precision machine tool that applies computer numerical control technology. The spindle axis is perpendicular to the horizontal plane, and the workpiece mounted on the worktable rotates within the horizontal plane, while the tool holder feeds vertically or diagonally. It is mainly used for processing workpieces with various types of structures such as disks, sleeves, rings, etc. Compared with traditional lathes, CNC vertical lathes have the characteristics of high precision, high degree of automation, strong flexibility, easy operation, and easy maintenance.

CNC vertical lathes are widely used in various industries such as aerospace, aviation, automotive, marine, power, bearings, and machinery, and are important mechanical equipment in industrial manufacturing. For example, in automobile manufacturing, it can be used to process some key parts of automobile engines; In the aerospace field, it can meet the machining needs of high-precision components.

CNC lathe plays a key role in industrial production, as it can achieve high-precision and high stability machining, ensure product quality and consistency, improve production efficiency, and reduce production costs. By using CNC systems and precision transmission components, it is possible to achieve millimeter level or even higher precision machining. Its mechanical structure layout reduces the load on the spindle and bearings, and can maintain high working accuracy. At the same time, the overall box type high-strength gray cast iron bed and high-precision ground ball screw pair design ensure the long-term stability and vibration resistance of the equipment.

High quality materials and manufacturing processes have high durability. For example, the spindle has good rigidity, high rotation accuracy, and is lubricated with grease. The entire shaft system has the characteristics of long service life, low temperature rise, good accuracy retention, and easy maintenance.

Processing steps:

Before starting up, confirm that the machine tool is in normal condition, check for lubricating oil and any other abnormal conditions.

Clamp the workpiece, confirm the clamping method based on the shape and processing method of the workpiece, find the center of the workpiece and copy the center coordinates.

Enter the program and start processing.

After processing, check the workpiece, unload the workpiece, and turn off the machine.

Operation method:

When clamping the workpiece, ensure that it is correctly clamped onto the machine tool and kept stable.

Choose the appropriate tool and select parameters such as cutting amount, cutting speed, and feed rate according to cutting requirements.

Operate the CNC system and process according to the program.

matters needing attention:

Before operation, it is necessary to carefully read the equipment manual and operating procedures, familiarize oneself with the equipment structure and functions.

When operating, follow the equipment operating procedures.

During cutting, equipment stability should be ensured to prevent workpiece resonance.

Numerical control machine tools are applied in the automotive manufacturing industry for processing automotive brake discs, pulleys, wheel hubs, and other components. Processing brake discs has the characteristics of high precision and high stability. It adopts an integral cast iron bed and high-precision ground ball screw pairs, with negative clearance, low resistance, and high rigidity. It is directly driven by an AC servo motor through a high rigidity coupling. The entire aircraft is controlled by a digital control system, with good rigidity and high rotation accuracy of the equipment spindle. Lubricated with grease, the entire shaft system has the characteristics of long service life, low temperature rise, good accuracy retention, and easy maintenance. At the same time, the equipment uses high-precision knife towers, which have high precision, fast indexing speed, and nearby tool selection functions.

As the main transmission component, the equipment screw adopts special technology for precision pre control of the screw rod. The accuracy impact caused by temperature changes, processing errors, and other reasons is pre adjusted in advance, which provides reliable guarantee for product processing and overall operation stability. The spindle and transmission components are carefully designed and manufactured to withstand long periods of heavy cutting.

CNC machining of brake discs can ensure the machining accuracy and quality of brake discs, and improve the reliability performance of automobiles.

Clamp the brake disc correctly onto the machine tool and maintain stability. Using a clamping device with clamping detection function to achieve automatic docking and ensure coaxiality requirements. Operate the CNC system and monitor the machining process.

Numerical control machine tools process water pumps and industrial machinery components, including outer cylindrical surfaces, conical surfaces, spherical surfaces, and threads, to ensure machining accuracy and quality.

More information

E-mail:meishenmeike@163.com

Zip Code: 215300

Add: No.68,Huangziliang Rd,Qutang Town, Hai'an City,Jiangsu

MEICO

Follow us