CNC vertical lathe: empowering high-precision manufacturing in the semiconductor industry

Release time:

2025-06-10

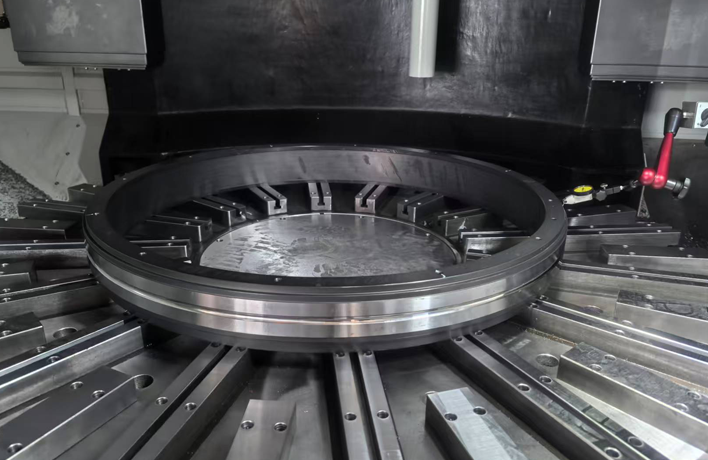

The fixture unit is connected to the CNC worktable through a hydraulic quick change joint, with a loading and unloading time of ≤ 2 minutes; Modular design supports expansion to double-layer or multi-layer workstations, further enhancing mass production capacity. For example, when processing semiconductor vacuum chamber components, the workpiece can be clamped simultaneously to complete inner and outer circular turning and end face groove processing.

The semiconductor industry has high requirements for the dimensional accuracy, surface quality, and production efficiency of parts, and traditional processing methods are difficult to meet its strict standards. The combination of CNC precision lathes(CNC vertical lathe) and multi station fixture technology provides an efficient, stable, and reliable solution for the manufacturing of key components in semiconductor equipment through high-precision transmission systems, automation control, and flexible design.

1、 Technical core: High precision and flexible collaboration

The CNC precision lathe adopts a high-precision servo motor and ball screw transmission system, combined with closed-loop grating scale feedback control, to achieve axial positioning accuracy and repeat positioning accuracy. This level of accuracy can meet the processing requirements of semiconductor vacuum chamber sealing surfaces, wafer carriers, and other parts, ensuring the assembly interactivity and functional reliability of the parts.

A CNC system controlled by computer programs can automatically complete multi process composite machining such as turning, drilling, milling, etc. Multi station fixtures, through modular design, support the simultaneous clamping of multiple workpieces, achieving "one-time clamping, continuous processing of multiple processes", reducing repeated positioning errors, and shortening single piece processing time by more than 50%.

The multi station fixture adopts a quick change interface and adjustable positioning structure, which can quickly adapt to workpieces of different sizes (such as metal flanges, bearings, locking discs, etc.). By replacing the fixture unit, the equipment can quickly switch from semiconductor fixture to cooling system components, improving production efficiency.

2、 Multi station fixture design: balance of precision, efficiency, and stability

High precision positioning and stable clamping

In response to the characteristics of easy deformation and strict dimensional tolerances of semiconductor components, the fixture adopts a composite structure of "three-point positioning+vacuum adsorption":

Positioning accuracy: By using precision pin holes and pneumatic positioning pins, the axial and radial positioning errors of the workpiece can be achieved;

Clamping force control: The vacuum suction pressure can be adjusted to avoid cracks in thin-walled ceramic parts (such as aluminum nitride substrates) caused by mechanical clamping;

Anti vibration design: The clamp adopts a high rigidity cast iron base and shock-absorbing rubber pad to suppress vibration transmission during high-speed cutting.

Fast loading and unloading and modular expansion

The fixture unit is connected to the CNC worktable through a hydraulic quick change joint, with a loading and unloading time of ≤ 2 minutes; Modular design supports expansion to double-layer or multi-layer workstations, further enhancing mass production capacity. For example, when processing semiconductor vacuum chamber components, the workpiece can be clamped simultaneously to complete inner and outer circular turning and end face groove processing.

The high-precision CNC system and stable fixture positioning greatly improve the qualification rate of parts;

Automated processing production lines avoid human errors, reduce manual intervention, precision cutting and fixture protection design, and ensure the interchangeability and functional reliability and stability of semiconductor equipment parts and materials.

CNC precision lathe and multi station fixture technology will be further integrated:

Integrated online measurement and adaptive compensation system, intelligent management, real-time correction of machining errors; Optimize the cutting fluid circulation system and lightweight design of fixtures to reduce energy consumption and environmental pollution.

The collaborative application of CNC precision lathes and multi station fixtures provides a full chain solution from design to mass production for the semiconductor industry. Through the integration of high-precision, high-efficiency, and high flexibility technologies, this combination not only meets the strict requirements of current semiconductor equipment manufacturing, but also lays a solid foundation for future technological iterations.

More information

E-mail:meishenmeike@163.com

Zip Code: 215300

Add: No.68,Huangziliang Rd,Qutang Town, Hai'an City,Jiangsu

MEICO

Follow us