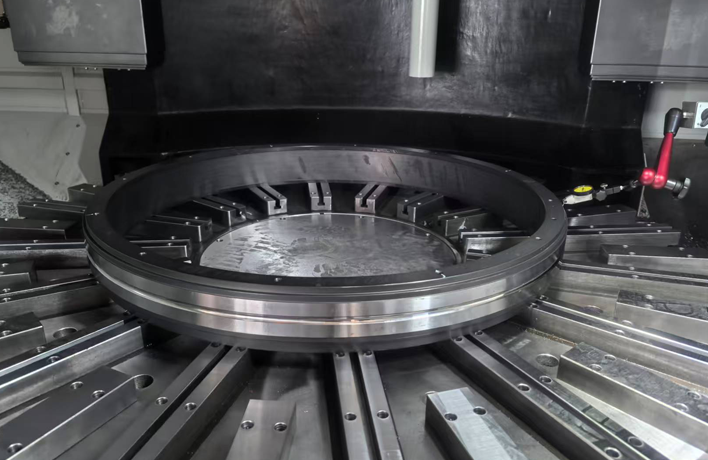

One clamping, double-sided molding: CNC lathe double-sided processing

Release time:

2025-06-17

A brake disc with a flange structure, double-sided processing can simultaneously ensure the perpendicularity of the flange surface and the friction surface, improving assembly accuracy. Wind turbine brake discs are double-sided processed with ventilation slots and heat dissipation holes. Simultaneous double-sided processing can avoid hole displacement caused by secondary clamping.

数控车床加工刹车盘:双面同步加工与平行度控制对汽车抖动的影响分析

1、 The direct correlation between brake disc processing quality and car vibration

Parallelism error leads to jitter mechanism

Dynamic imbalance principle: If there is a parallelism deviation between the two friction surfaces of the brake disc, centrifugal force will cause the brake disc to oscillate periodically during high-speed braking. This oscillation is transmitted to the suspension system through the wheel hub bearings, ultimately causing steering wheel or body shaking.

Case analogy: Similar to the severe vibration caused by uneven distribution of clothes in a washing machine, the parallelism deviation of the brake disc will amplify the dynamic imbalance during braking.

The superposition effect of processing defects

Surface roughness: Traditional single-sided processing requires secondary clamping, and the other side cannot be processed synchronously. This may cause deformation of the processed surface due to the release of clamping stress, and the deterioration of roughness will exacerbate uneven friction.

Thickness deviation: Non synchronous processing on both sides can easily lead to excessive thickness tolerance, and the difference in friction between the two sides during braking can cause shaking.

2、 The Technical Necessity of Double sided Synchronous Machining on CNC Lathes

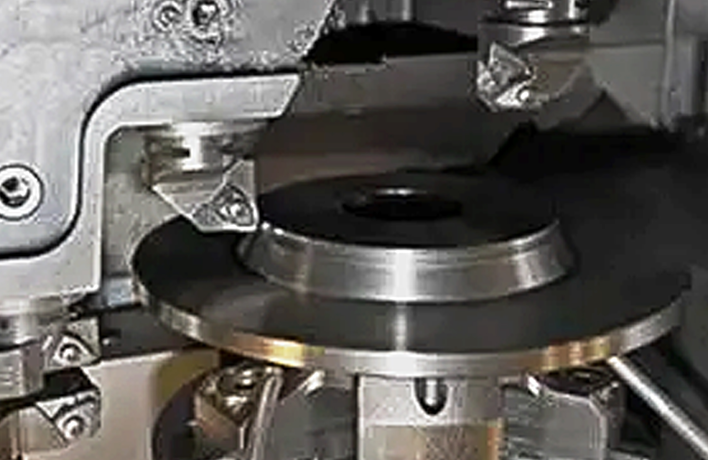

Double blade holder synchronous control, using CNC system linkage control to ensure simultaneous feed of two blades, can control parallelism error, and error compensation accuracy.

By using hydraulic chuck clamping force, machining vibration is reduced to ensure consistency in double-sided cutting.

Integrated laser rangefinder for real-time monitoring of double-sided parallelism and dynamic adjustment of tool compensation values.

3、 The key process of parallelism control

Soft Claw Design: Using polyurethane or nylon soft claws to avoid scratching the brake disc end face and provide uniform clamping force.

Central positioning accuracy: Coaxial positioning is achieved through hydraulic expansion sleeve, reducing clamping errors.

Double sided cutting force balance: spindle speed control, feed rate coordination, ensuring symmetrical double-sided cutting force.

Geometric parameters of cutting tools: Use tools with front and back angles to reduce the impact of cutting heat on parallelism.

Thermal deformation compensation

Constant temperature processing environment: workshop temperature control, machine tool spindle box adopts oil cooling circulation system, temperature fluctuation should not be too large.

Thermal error modeling: Establish a thermal deformation prediction model through finite element analysis (FEA) to pre compensate for tool paths.

A brake disc with a flange structure, double-sided processing can simultaneously ensure the perpendicularity of the flange surface and the friction surface, improving assembly accuracy. Wind turbine brake discs are double-sided processed with ventilation slots and heat dissipation holes. Simultaneous double-sided processing can avoid hole displacement caused by secondary clamping.

4、 Quality inspection and verification methods

Coordinate Measuring Machine (CMM)

Testing items: double-sided parallelism, flatness, thickness difference.

Standard requirements: parallelism, flatness, and thickness difference detection.

Braking jitter simulation test

Bench test: On the inertia braking test bench, brake at an initial speed of 120km/h and detect the acceleration of steering wheel vibration.

Real vehicle road test: Drive on bumpy roads to verify if the brake shake is reproduced.

The double-sided synchronous machining process of Meishen Meike CNC lathe is a key technology to ensure the parallelism of brake discs, which can effectively eliminate the root cause of brake vibration. Parallelism control, combined with thermal deformation compensation and online measurement, can achieve a qualification rate of over 99%.

More information

E-mail:meishenmeike@163.com

Zip Code: 215300

Add: No.68,Huangziliang Rd,Qutang Town, Hai'an City,Jiangsu

MEICO

Follow us